Hi all,

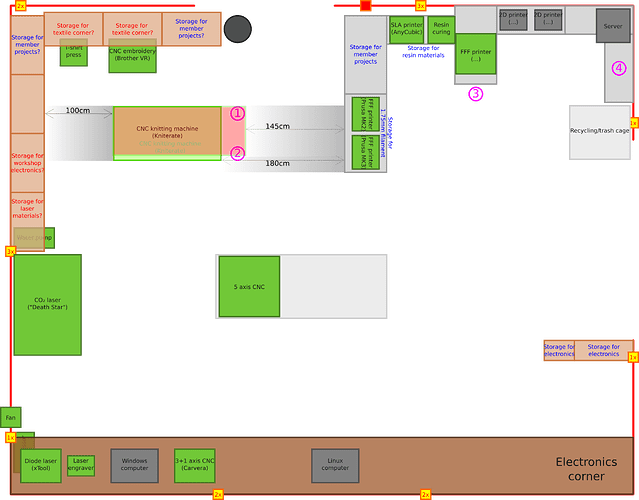

A new machine — the Kniterate (for details, ask Pat) — will soon be added to the Starship Factory. Its dimensions (including access area) are approximately 3x2m.

As there is no obvious place for this machine within the current SF layout, we’ll need to update the layout to accommodate the machine. While doing so, let’s make things a bit more practical, in the following sense:

-

Grouping machines by theme. In other words, a textile corner (Kniterate, Brother VR embroidering machine, T-shirt press), laser corner (“Death star”, xTool, laser engraver), updated FFF- and SLA 3D-print and 3D-scan area, including all filament and resin, CNC corner with the Carvera and perhaps the 5-axis mill, …

-

More space for members to (temporarily) store their personal projects. Dedicated shelves — and tops of shelves — would be great. Boxes belonging to former/inactive owners could perhaps be placed on shelves in the corridor outside the SF.

To help with an updated layout, I made a simple sketch of the current layout, here attached as SVG file (right-click → Save image as…). Using Inkscape, Illustrator or another vector editor, you can easily move shelves/machines/… around in the search for an updated layout. Please download it, play with it, and don’t hesitate to share your results!