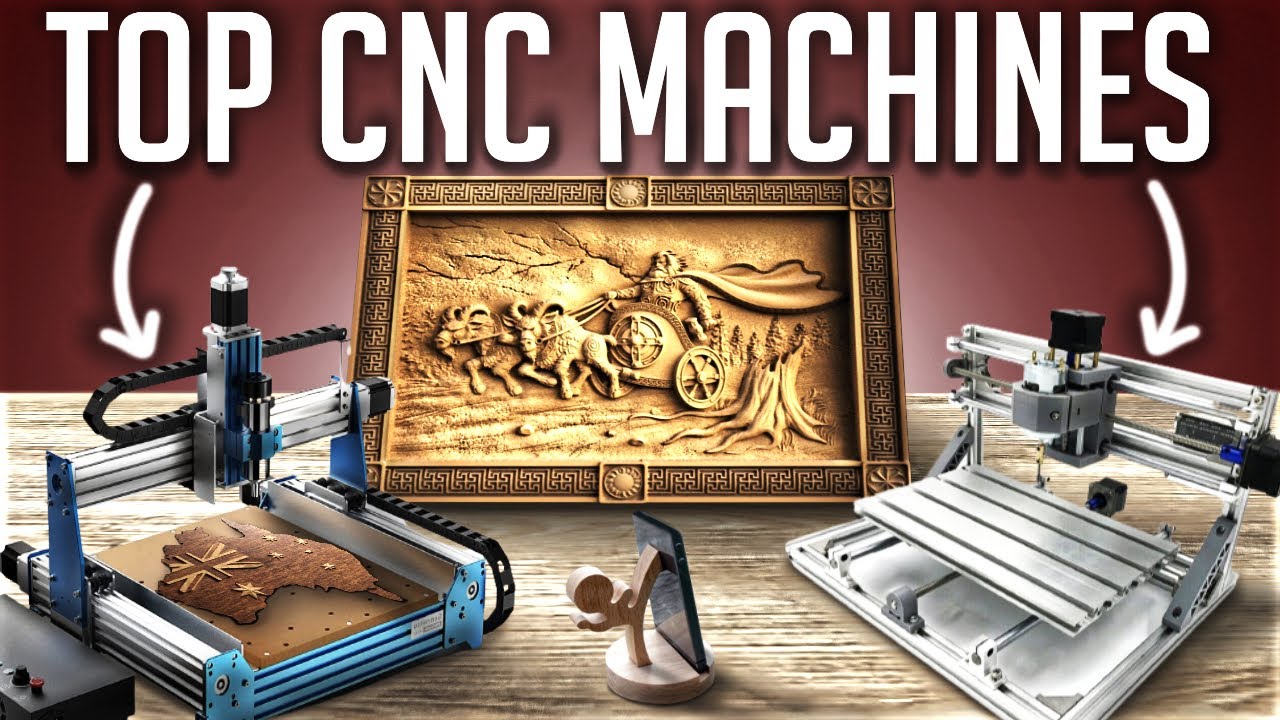

I quite enjoy playing with the Genmitsu 3018 ProVer CNC router. The tiny machine is quite remarkable. @Alex Thanks for letting me use it!

Albeit I have been able to produce first good results, I am struggling to achieve good feed rates while working with wood.

Even on soft wood I appear to be limited to low feed rates in the order of 30 mm/min. Higher feed rates up to 60 mm/min are possible, but the machine becomes very noisy in these cases. I have not dared to go further.

In the absence of alternatives, I have been using the Genmitsu Nano Blue Coat Router bits, which come with the machine (see photos below). So far, I have not played with the spindle rate, but always set it to the maximum of 10’000 rpm.

What am I missing? Is it due to the router bits I am using? Do I need a different feed/rotation rate combination? Or is the noise simply part of the process?

Is anyone able to provide advice?

In order to check on the bits, I have ordered the following alternatives:

I am planning to report the results later.

Cheers,

Bernd

–

1 „Gefällt mir“

Hi Bernd,

This is a good general overview, relating the different values/settings (e.g. chip load, number of flutes, RPM, horizontal feedrate, depth of cut, tool engagement, …) to each other — Guide: Understanding and choosing CNC Feeds and Speed | MEKANIKA

2 „Gefällt mir“

BTW This is one of the best videos that I have found so far. It explains all the basic terms that you need to understand for the CNC world in the simplest way

Don’t Stuck due to title of the video presenter goes way beyond selecting machine

1 „Gefällt mir“

Thanks to both of you. This is good stuff. Very helpful.

1 „Gefällt mir“

Short update after a view more experiments:

I finally ordered these bits. The new bits were better than the ones supplied with the mill (at least for spruce wood), but overall the problem of low performance remained. I achieved something like 120 mm/min feed rate at 10k rpm before the strange noises and vibrations started again.

In the end it turned out that the spindle drive was defect. After I had replaced the original drive with the somewhat stronger 20k rpm variant I realized that the 10k rpm on the original drive were never ever 10k.

The new drive seems to spin much faster (visual impression), produces a higher frequency and louder noise, and I finally burn my fingers (from friction) when I gently touch the ER11 during operation

With the new drive, I get much better performance. In my last attempt, I achieved a feed rate of 300 mm/min with spruce wood at 4000 rpm. Since the drive can do up to 20’000 rpm and has a power consumption of up to 100W a lot more seems feasible (until the router bit breaks or melts away).

Overall, I am happy now. I still seem to need higher spindle speeds than you can find in the various tables in the net. I assume the reason is the low sturdiness of the mill and possible also the low power and hece torque of the drive. The consequence is probably short bit life and also the chips are very fine, which is a challenge for my vacuum cleaner.

Let us see how much more I can get out of this machine.